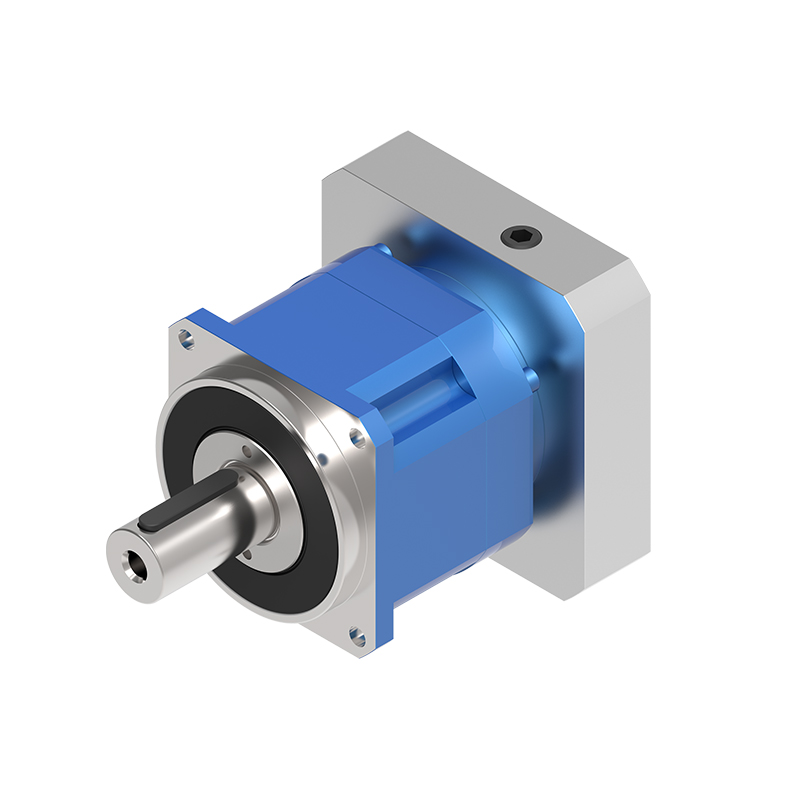

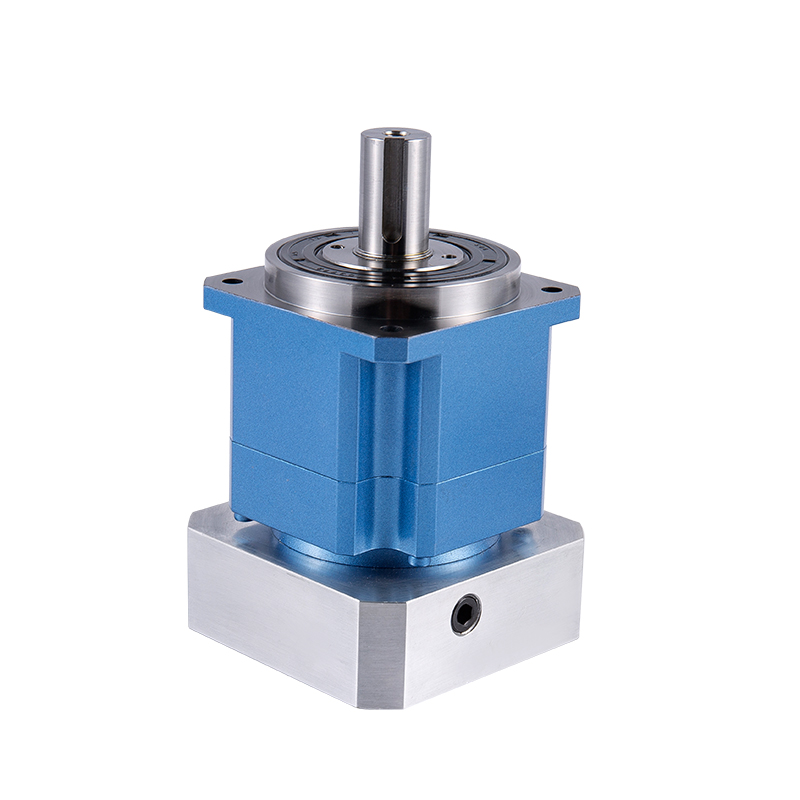

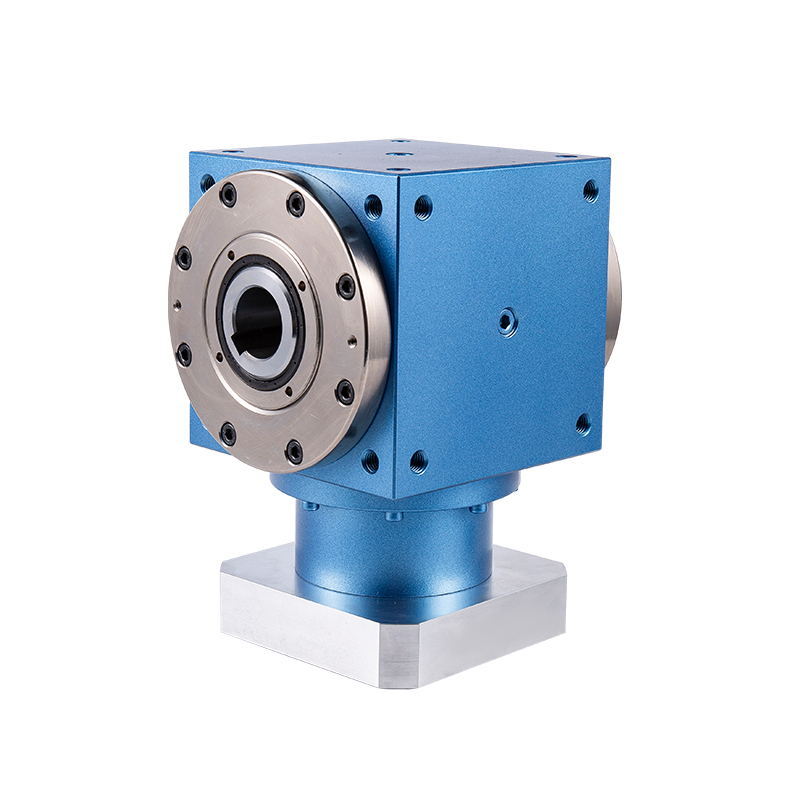

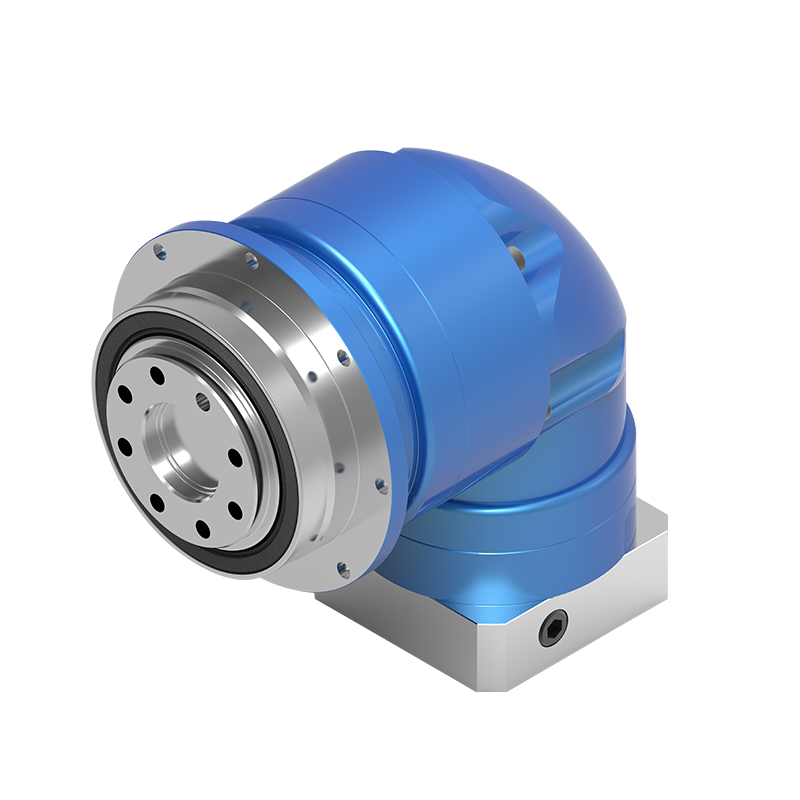

1. Helical gear design

The speed reduction mechanism adopts a helical gear design, and its tooth meshing rate is more than twice that of general spur gears. It has the characteristics of smooth operation, low noise, high output torque, and low backlash

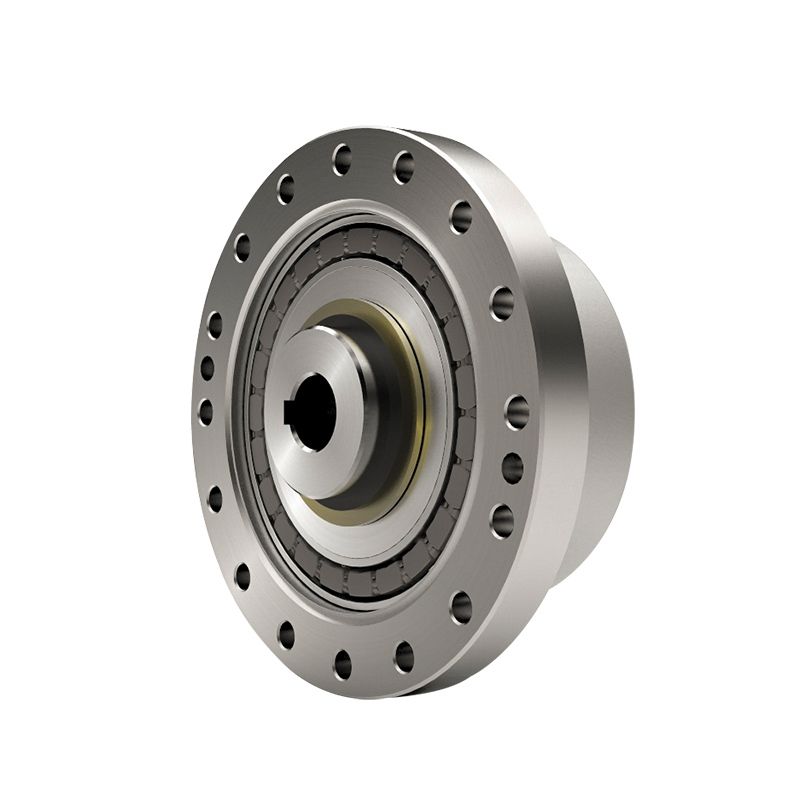

2. Collet-type locking ring structure

The connection between the input end and the motor adopts a collet-type locking ring structure and undergoes dynamic balancing analysis to ensure the concentricity of the interface and zero backlash power transmission at high input speed

3. Modular design of motor connection flange

The unique modular design of the motor connection flange and shaft is suitable for servo motors of any brand and type

4. Environmentally friendly surface treatment technology

The surface of the gearbox is sprayed with environmentally friendly water-based paint to improve environmental tolerance and corrosion resistance

5. The output end of the reducer adopts a carefully designed through-hole structure. This design allows users to easily pass the screws through the motor end, thereby ensuring a firm connection between the reducer and the customer's equipment, ensuring the overall stability and operating efficiency of the equipment. In order to ensure the accurate installation and firm fixation of the reducer and customer equipment, we have specially set holes at the output end. Users can use these through holes to directly pass the screws through the motor end and fix the reducer tightly to the equipment, effectively preventing operational problems that may be caused by loosening or offset.

Home / Products / Planetary Reducer / High Precision Low Noise NHB Planetary Reducer Gearbox Drive for Servo Motor

High Precision Low Noise NHB Planetary Reducer Gearbox Drive for Servo Motor

About Us

Zhejiang Beitto Transmission Technology Co., Ltd.

The company has always adhered to the Japanese electromechanical cutting-edge R & D technology, adhering to the Japanese meticulous production process, the use of leading design and development technology to research new products, to achieve the optimization and upgrading of the product structure renewal. As a China Servo Motor Planetary Gearbox and Wholesale Low Backlash Planetary Gearbox Factory, we offer Stepper Motor Planetary Gearbox.

The city - Pinghu City, Zhejiang Province, National Economic and Technological Development Zone, the province's only one approved by the provincial government of the Japanese investment zone, the National (Jiaxing) Electromechanical Components Industrial Park and the National Torch Plan Pinghu Optical and Mechanical Industrial Base core area, Pinghu City is located in China's most dynamic economy of the Yangtze River delta region, is located in the northeastern part of Zhejiang Province, east of China's economic, financial, and information center -It is located in the northeastern part of Zhejiang Province, neighboring Shanghai to the east and Hangzhou Bay to the south. The city has a land area of 537 square kilometers, a sea area of 1,086 square kilometers and a coastline of 27 kilometers. It has a total population of 800,000 people.

News

-

In the realm of precision automation, robotics, and high-performance machinery, the seamless convers......

READ MORE -

In the intricate world of mechanical engineering and power transmission, the evolution of components......

READ MORE -

The seamless integration of motion control components is the cornerstone of modern automation, robot......

READ MORE -

In the world of precision motion control and power transmission, few components are as critical and ......

READ MORE -

In the world of industrial automation and precision motion control, the choice of a power transmissi......

READ MORE -

The Role of Precision Motion Control in Modern Automation At the heart of advanced robotics and soph......

READ MORE

EN

EN

English

English русский

русский 日本語

日本語 Español

Español