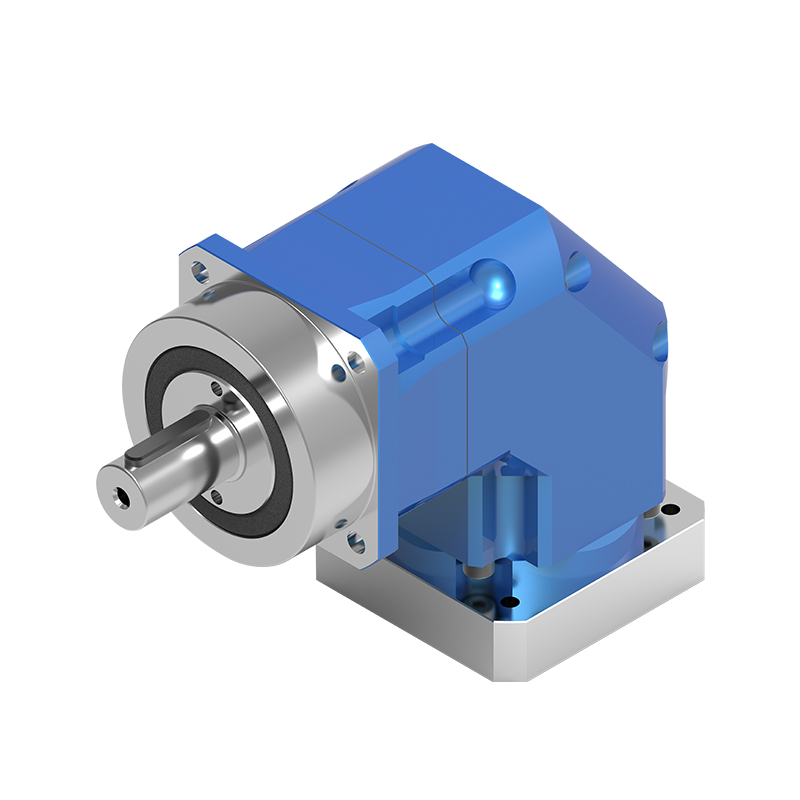

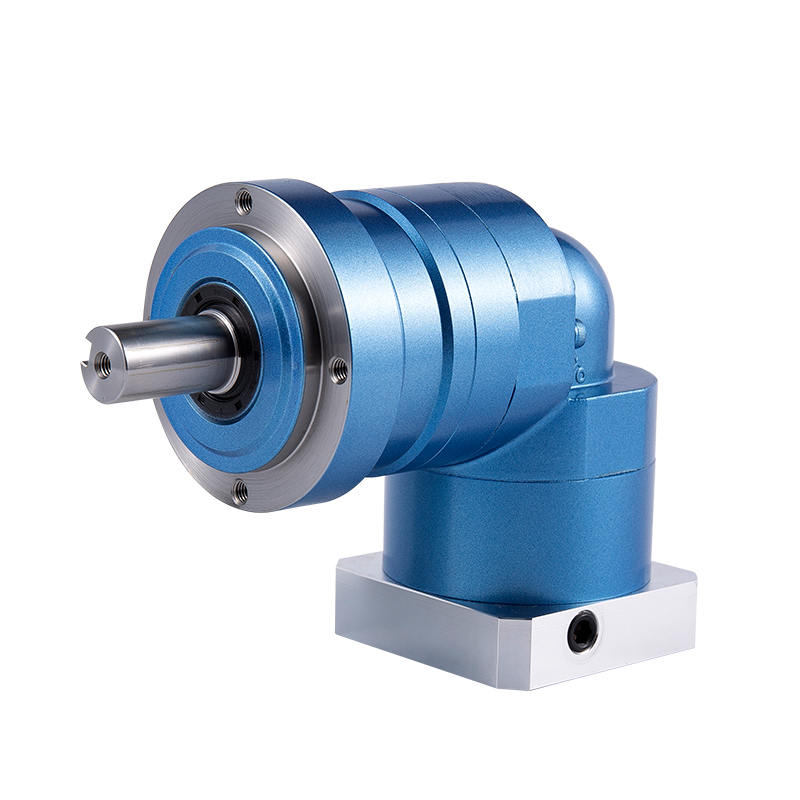

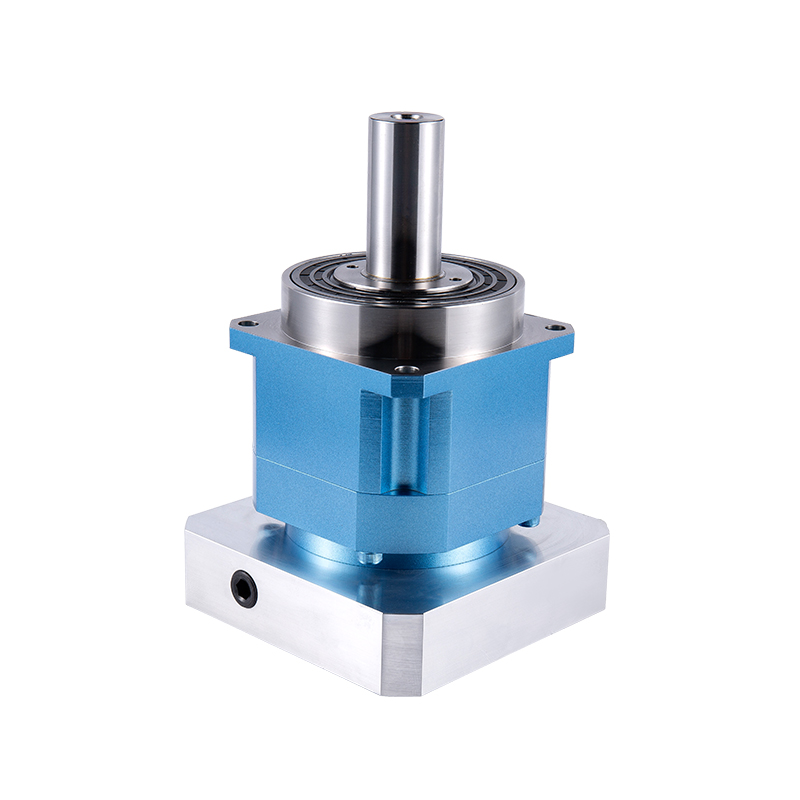

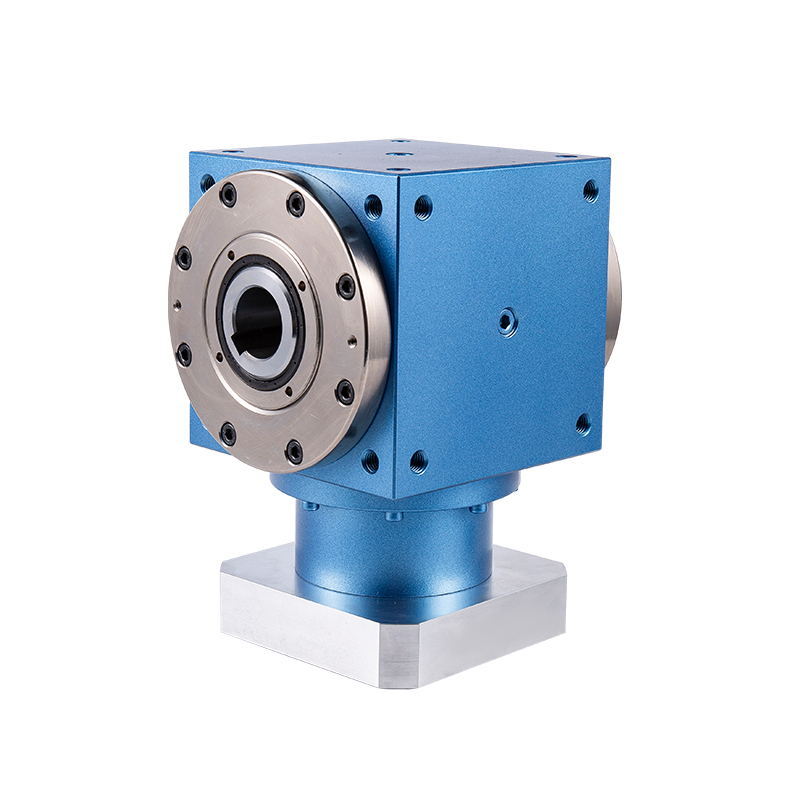

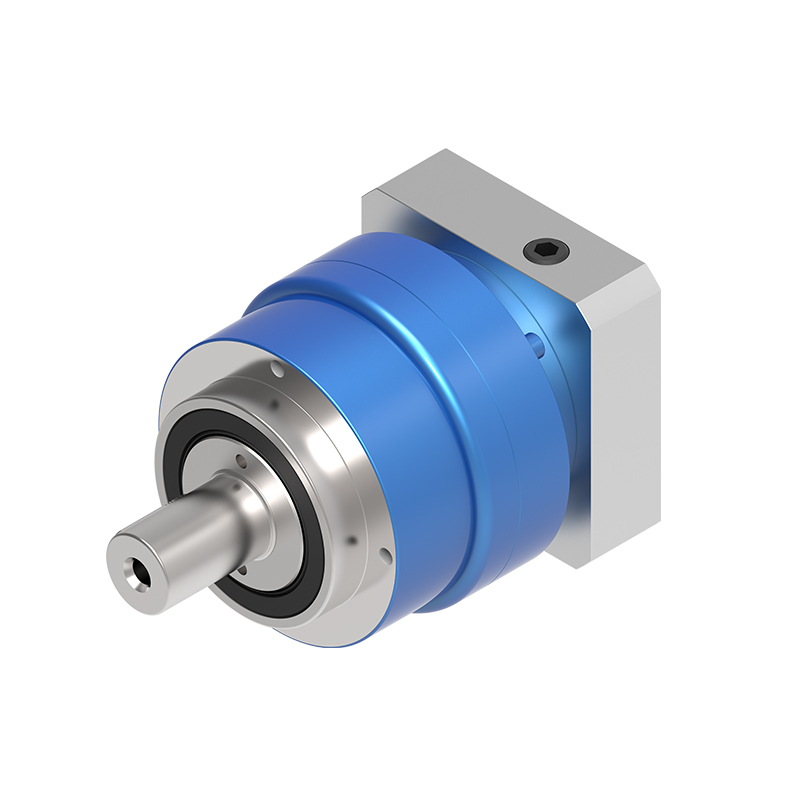

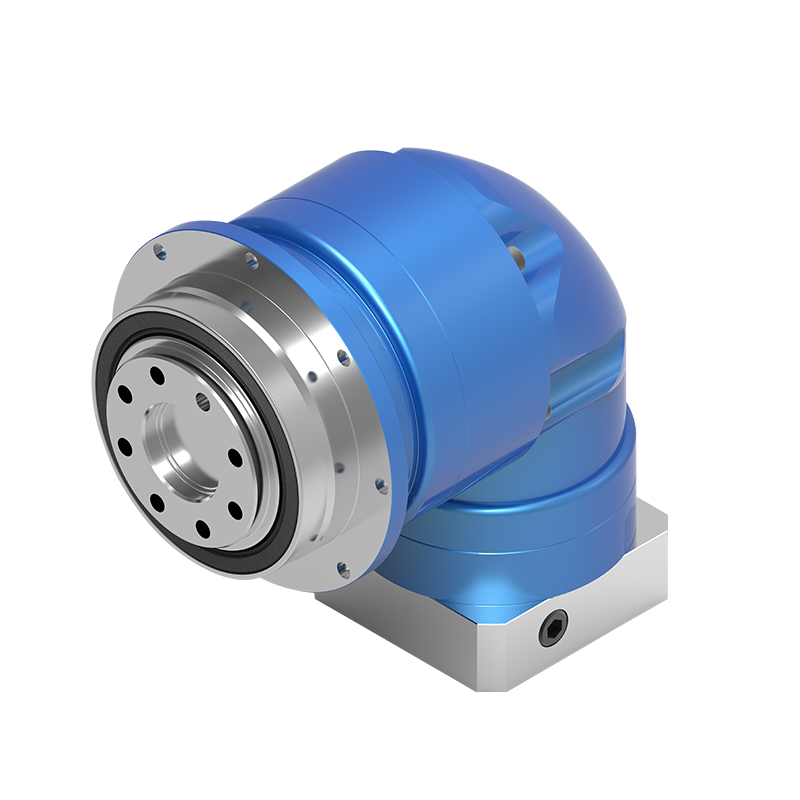

The NSR series planetary reducer adopts a spiral bevel gear design. This innovation not only makes the output torque more than 30% higher than that of spur bevel gears, but also achieves a high rated input speed, which is more than 8 times higher than that of traditional spur bevel gears. This means that under the same conditions, the NSR series can carry a larger load and achieve a faster speed, bringing higher efficiency and capacity to your production line. The meshing tooth print of the spiral bevel gear has been optimized to make the contact tooth surface load uniform, effectively extending the operating life of the reducer. At the same time, through optimized motion error analysis and strict process control, the reducer is ensured to have a high-precision operating backlash (≤2arcmin), providing you with a more stable and reliable transmission effect.

The gearbox structure of the NSR series adopts a high-strength and lightweight aluminum alloy design, which not only has extremely high rigidity, but also reduces the overall weight, making it easy to install and maintain. This design not only improves the durability of the reducer, but also reduces production and transportation costs.

The NSR series planetary reducer adopts a maintenance-free design, without the need to regularly replace lubricating oil, which greatly reduces maintenance costs and downtime. At the same time, its high efficiency (more than 95%) and low noise (less than 61dB) also make it an environmentally friendly and energy-saving product.

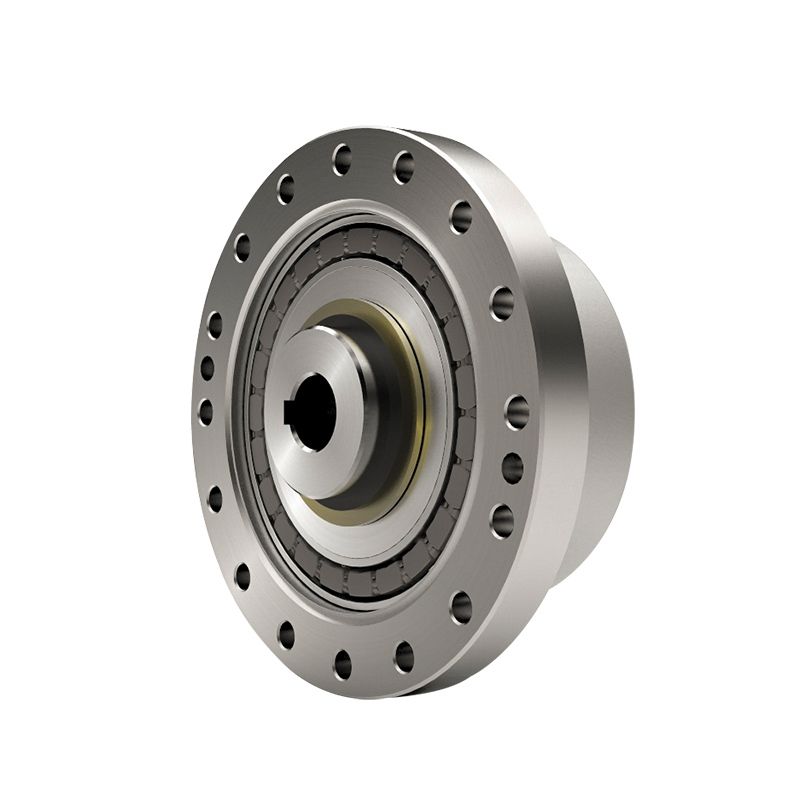

In order to meet the needs of different customers, the NSR series provides 23 reduction ratios for you to choose from, from i=3 to i=200. No matter what reduction ratio your production line requires, you can find a suitable product. In addition, we have also specially increased the contact area of the output end to obtain a higher load capacity to ensure that the reducer can still operate stably under harsh working conditions.

Home / Products / Planetary Reducer / Low Noise High Rigidity Servo Motor Speed Reducer NSR Series Planetary Reducer

Low Noise High Rigidity Servo Motor Speed Reducer NSR Series Planetary Reducer

About Us

Zhejiang Beitto Transmission Technology Co., Ltd.

The company has always adhered to the Japanese electromechanical cutting-edge R & D technology, adhering to the Japanese meticulous production process, the use of leading design and development technology to research new products, to achieve the optimization and upgrading of the product structure renewal. As a China Low Noise High Rigidity Servo Motor Speed Reducer NSR Series Planetary Reducer Manufacturers and Wholesale Low Noise High Rigidity Servo Motor Speed Reducer NSR Series Planetary Reducer Factory, we offer Low Noise High Rigidity Servo Motor Speed Reducer NSR Series Planetary Reducer.

The city - Pinghu City, Zhejiang Province, National Economic and Technological Development Zone, the province's only one approved by the provincial government of the Japanese investment zone, the National (Jiaxing) Electromechanical Components Industrial Park and the National Torch Plan Pinghu Optical and Mechanical Industrial Base core area, Pinghu City is located in China's most dynamic economy of the Yangtze River delta region, is located in the northeastern part of Zhejiang Province, east of China's economic, financial, and information center -It is located in the northeastern part of Zhejiang Province, neighboring Shanghai to the east and Hangzhou Bay to the south. The city has a land area of 537 square kilometers, a sea area of 1,086 square kilometers and a coastline of 27 kilometers. It has a total population of 800,000 people.

News

-

In the world of precision motion control and power transmission, the planetary gearbox stands as a c......

READ MORE -

Understanding the Role of Right-angled Gearbox Reducer in Modern Machinery How Right-Angled Gearbox ......

READ MORE -

The industrial landscape is constantly pushing the boundaries of automation, requiring smaller, fast......

READ MORE -

Understanding the Fundamental Principles of Harmonic Drive Systems The Unique Mechanical Architectur......

READ MORE -

In the world of precision motion control, the integration of a stepper motor planetary gearbox repre......

READ MORE -

1. What is a planetary gear reducer? Definition and basic operating principle A planetary gear redu......

READ MORE

EN

EN

English

English русский

русский 日本語

日本語 Español

Español