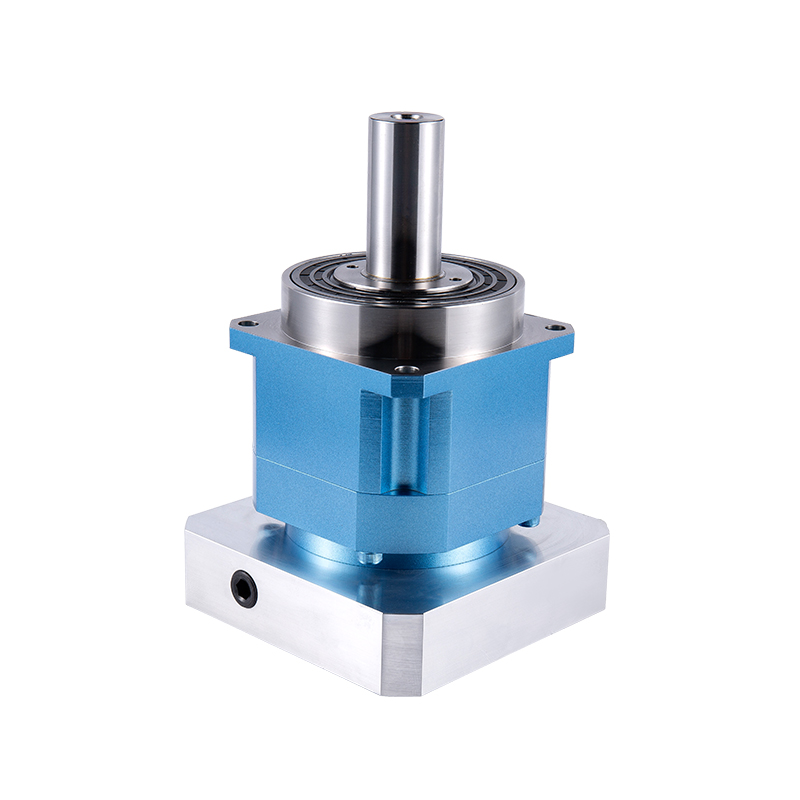

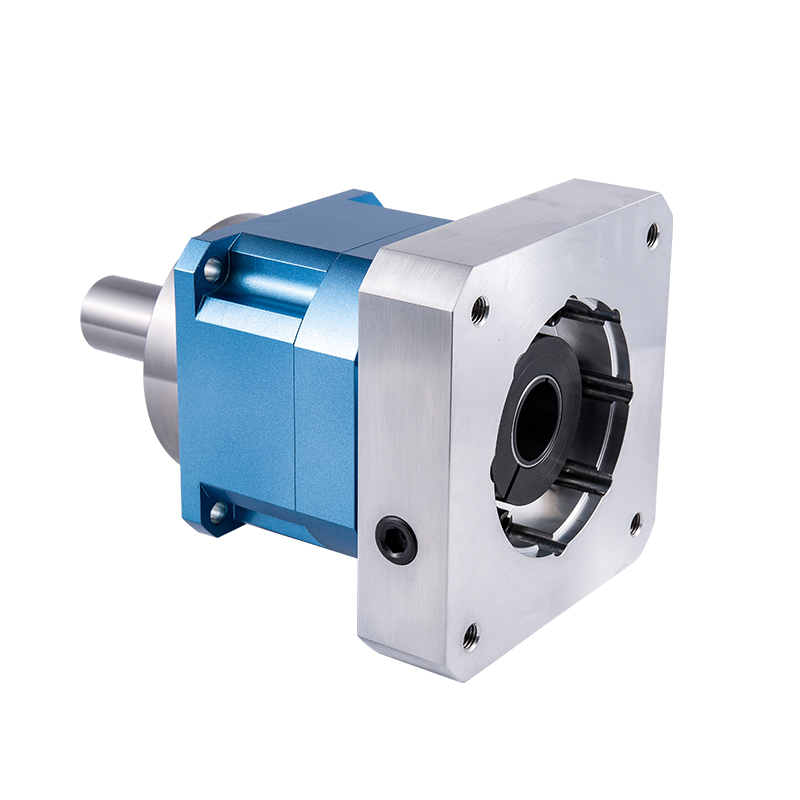

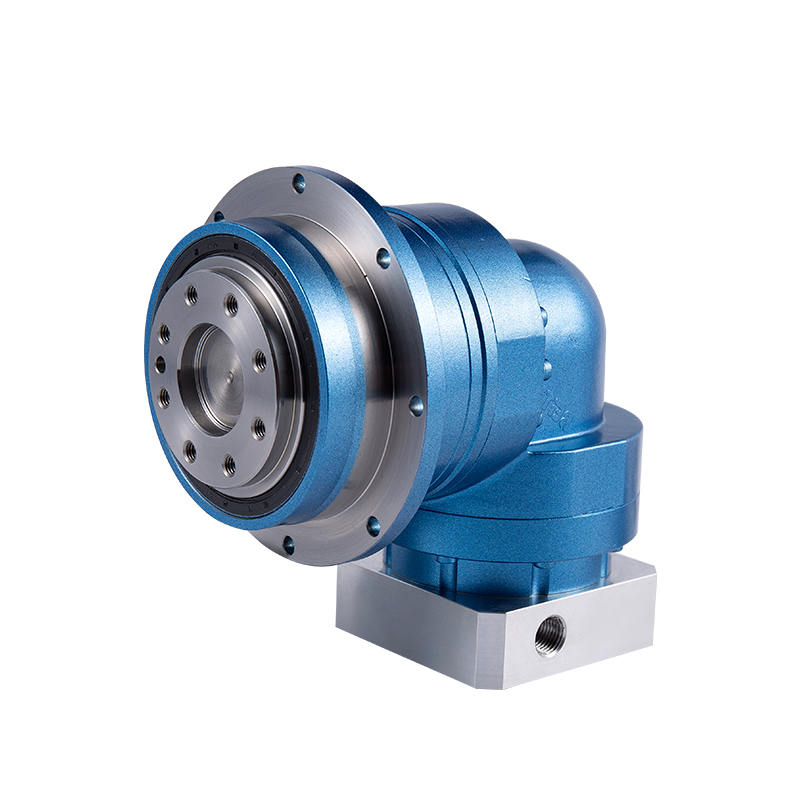

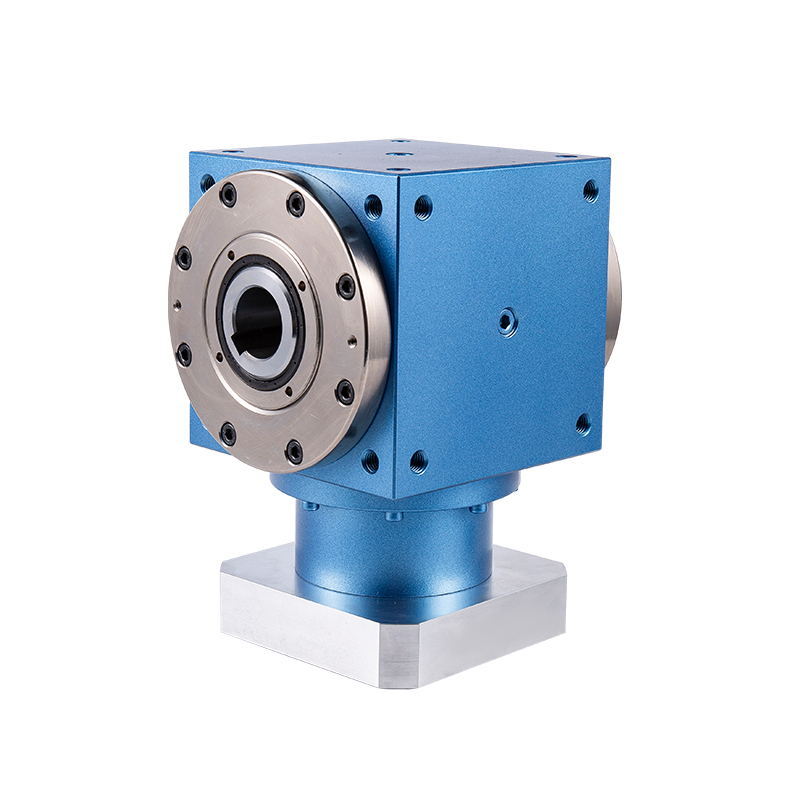

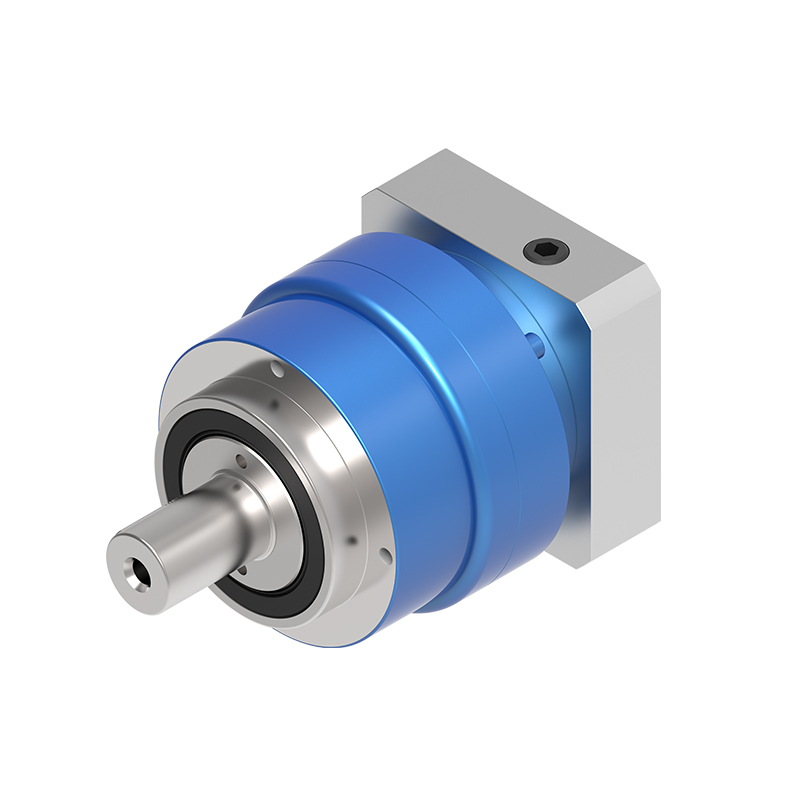

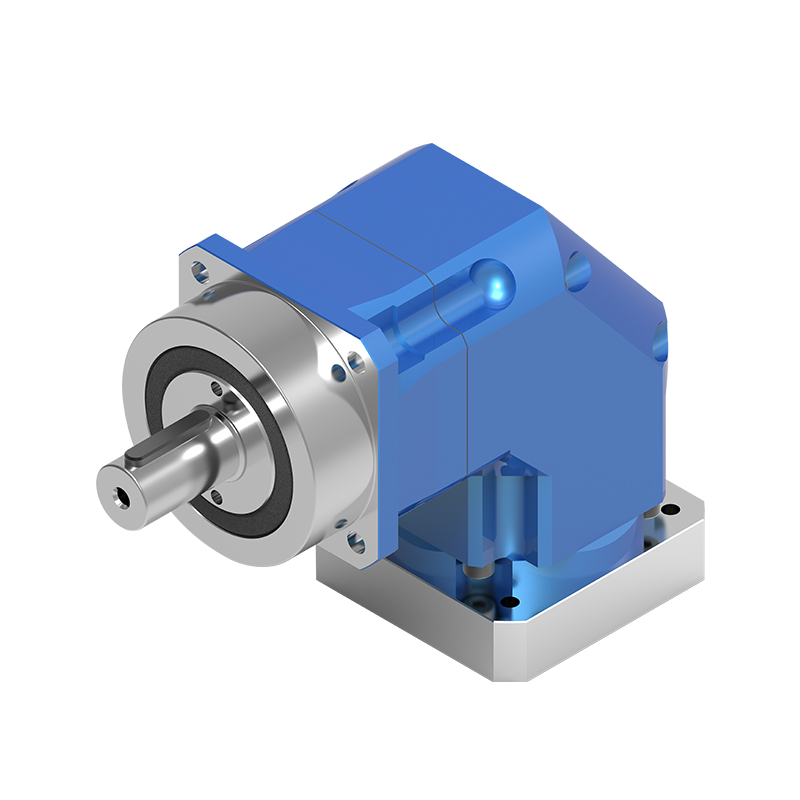

Our reducers incorporate the cutting-edge design concept of helical gears. Compared with traditional spur gears, their tooth meshing ratio has achieved a qualitative leap, at least doubled. This innovation not only ensures the ultimate smoothness of the reducer's operation, but also greatly reduces noise interference, significantly enhances the output torque, and achieves efficient transmission with almost no backlash. In order to ensure the accuracy and stability of power transmission at high speeds, we have carefully created a collet-type locking mechanism. After strict dynamic balancing analysis, we ensure that the concentricity of the connection interface meets the standards and achieves smooth transmission with zero backlash. In addition, our innovative motor connection flange and shaft modular design show compatibility and flexibility, easily adapting to various servo motor brands and models, and providing users with a wide range of solutions. The surface of the gearbox is sprayed with environmentally friendly water-based paint to improve environmental tolerance and corrosion resistance, ensuring the long-term stability and reliability of the reducer. In order to ensure that the reducer still maintains stable performance when subjected to high loads, we have specially optimized the design of the output end to increase its contact area. This improvement not only increases the load-bearing capacity of the output end but also makes the load distribution more uniform, thereby significantly enhancing the overall strength of the reducer. Considering the high-intensity load conditions that may be encountered in actual applications, we have finally determined the solution to increase the contact area of the output end through precise calculations and simulation analysis.

Home / Products / Planetary Reducer / Full Metal High Precision Torque Planetary Gearbox Speed Reducer NHS series

About Us

Zhejiang Beitto Transmission Technology Co., Ltd.

The company has always adhered to the Japanese electromechanical cutting-edge R & D technology, adhering to the Japanese meticulous production process, the use of leading design and development technology to research new products, to achieve the optimization and upgrading of the product structure renewal. As a China Full Metal High Precision Torque Planetary Gearbox Speed Reducer NHS series Manufacturers and Wholesale Full Metal High Precision Torque Planetary Gearbox Speed Reducer NHS series Factory, we offer Full Metal High Precision Torque Planetary Gearbox Speed Reducer NHS series.

The city - Pinghu City, Zhejiang Province, National Economic and Technological Development Zone, the province's only one approved by the provincial government of the Japanese investment zone, the National (Jiaxing) Electromechanical Components Industrial Park and the National Torch Plan Pinghu Optical and Mechanical Industrial Base core area, Pinghu City is located in China's most dynamic economy of the Yangtze River delta region, is located in the northeastern part of Zhejiang Province, east of China's economic, financial, and information center -It is located in the northeastern part of Zhejiang Province, neighboring Shanghai to the east and Hangzhou Bay to the south. The city has a land area of 537 square kilometers, a sea area of 1,086 square kilometers and a coastline of 27 kilometers. It has a total population of 800,000 people.

News

-

Introduction to High-Precision Gear Reducer The High-Precision Gear Reducer plays a crucial role in ......

READ MORE -

In the world of precision motion control and power transmission, the planetary gearbox stands as a c......

READ MORE -

Understanding the Role of Right-angled Gearbox Reducer in Modern Machinery How Right-Angled Gearbox ......

READ MORE -

The industrial landscape is constantly pushing the boundaries of automation, requiring smaller, fast......

READ MORE -

Understanding the Fundamental Principles of Harmonic Drive Systems The Unique Mechanical Architectur......

READ MORE -

In the world of precision motion control, the integration of a stepper motor planetary gearbox repre......

READ MORE

EN

EN

English

English русский

русский 日本語

日本語 Español

Español