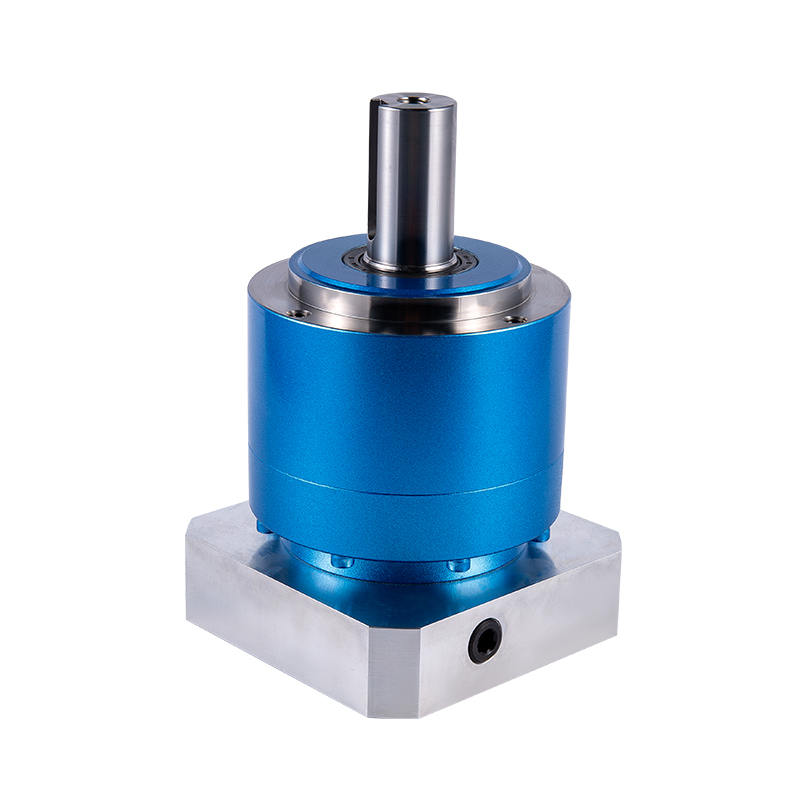

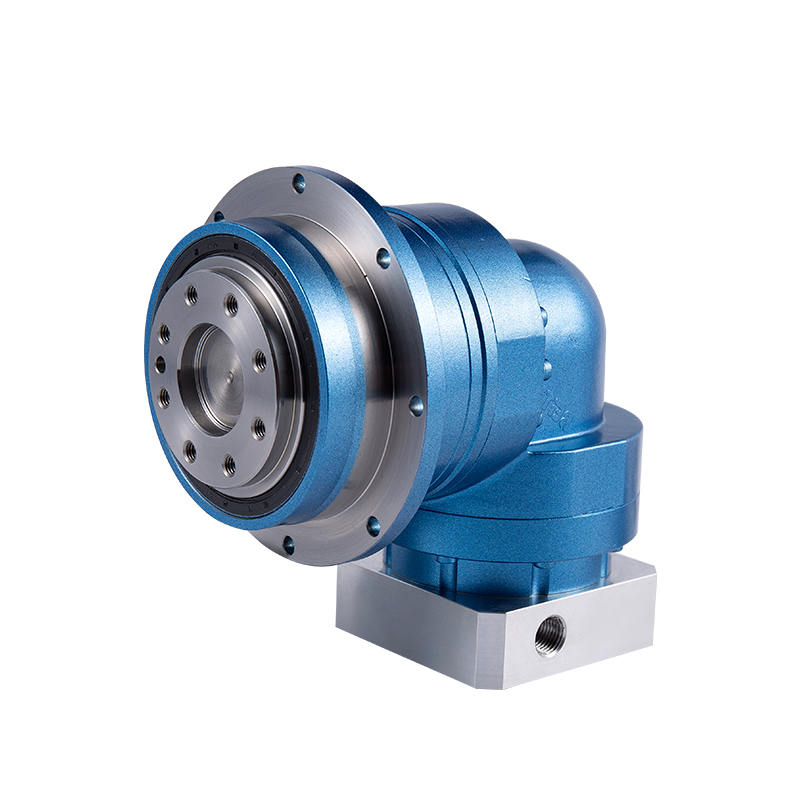

Planetary reducers have been widely used in many industries for their performance. Their uniquely designed helical gears ensure extremely smooth operation and low noise, providing users with a quiet working environment.

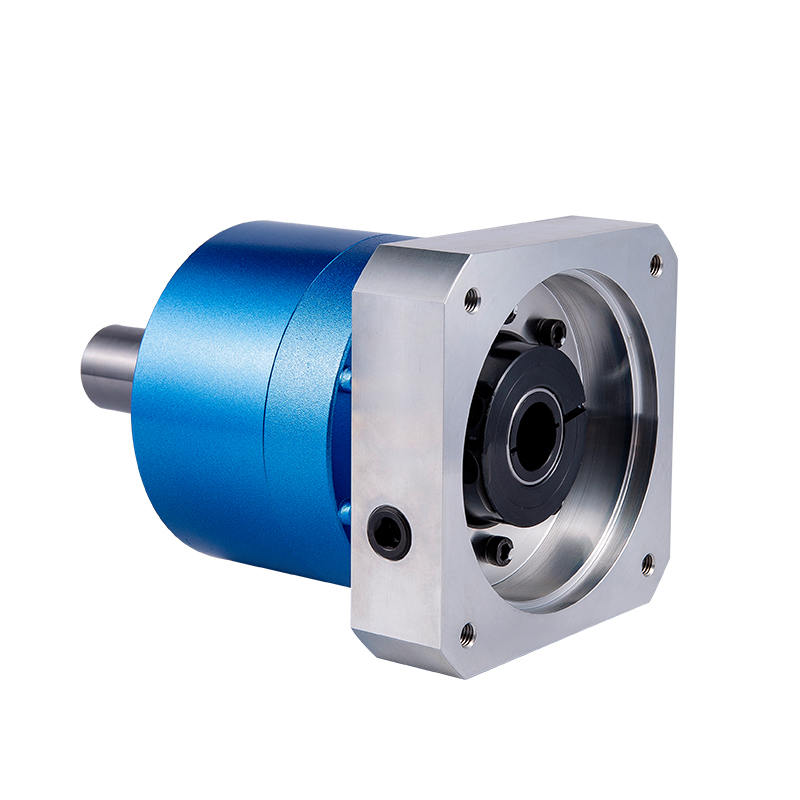

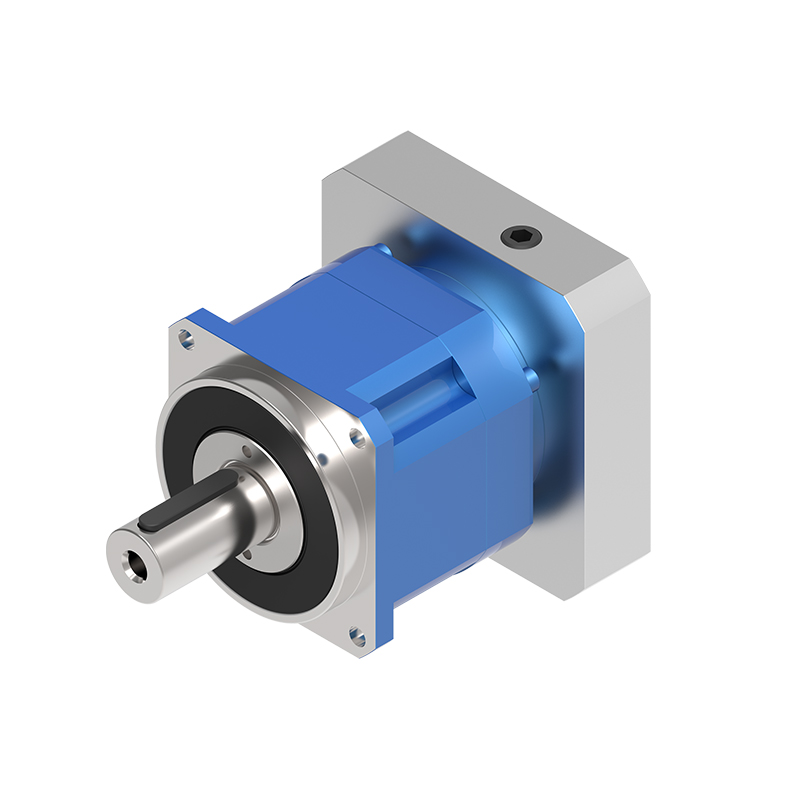

In terms of mechanical performance, the planetary reducer uses integral ball bearings, which significantly improve its rigidity and torque output capacity, meeting high-load and high-demand working environments. At the same time, it provides flexible flange and connector methods to ensure seamless docking with various motors around the world, achieving wide compatibility.

In terms of lubrication, the planetary reducer uses high-viscosity, non-separable grease, which effectively prevents grease leakage and ensures long-term stable operation of the equipment. Moreover, there is no need to replace the grease throughout the life cycle of the product, which greatly reduces the complexity and cost of maintenance.

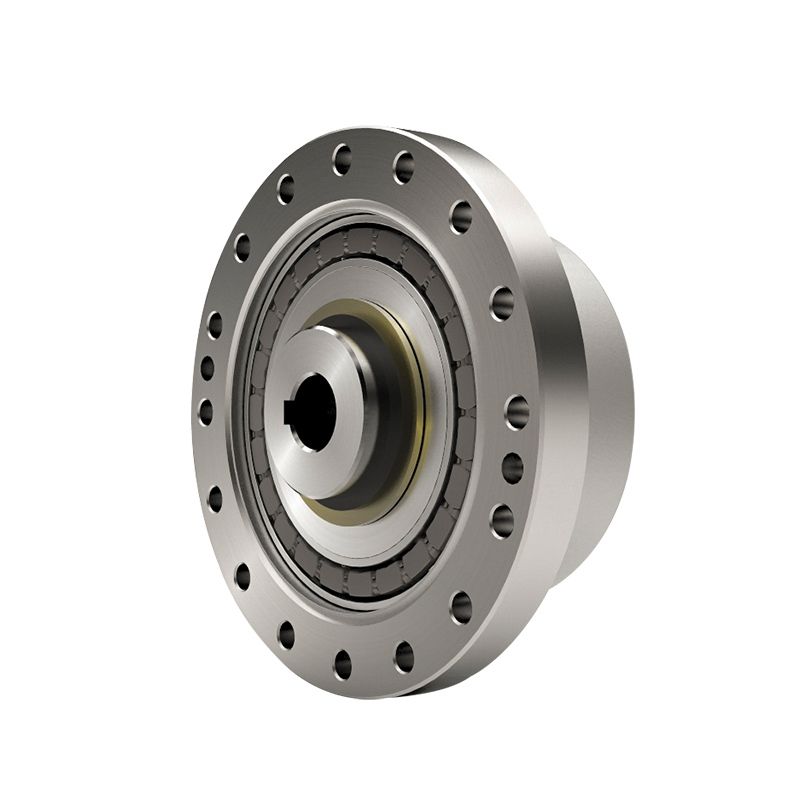

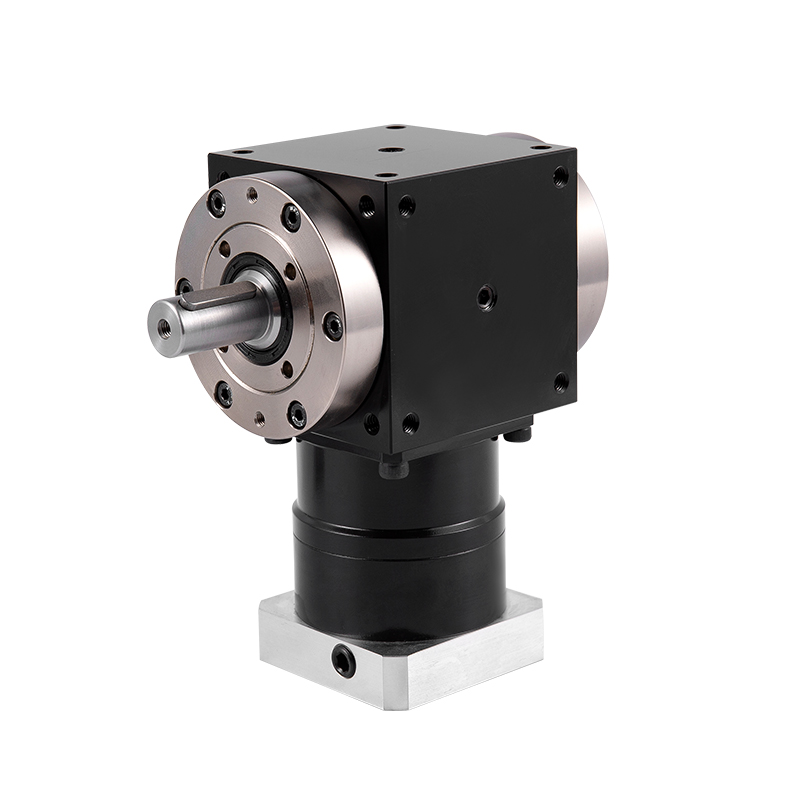

In the design of the planetary reducer, the ingenious layout of the output end screw holes not only ensures the stability of the structure but also greatly improves the convenience of installation. These screw holes are designed for screws of specific sizes. When the screws pass through the equipment end, they can tightly connect the reducer to the customer's equipment, ensuring stable operation in various working environments.

This planetary reducer is widely used in industrial automation, mobile robots, SCARA robots, parallel manipulators, printing machinery, laser cutting machines, packaging machinery, pharmaceutical machinery, pipe bending machines, spring machines, and non-standard automation equipment, etc., becoming an indispensable component in the modern industrial field.

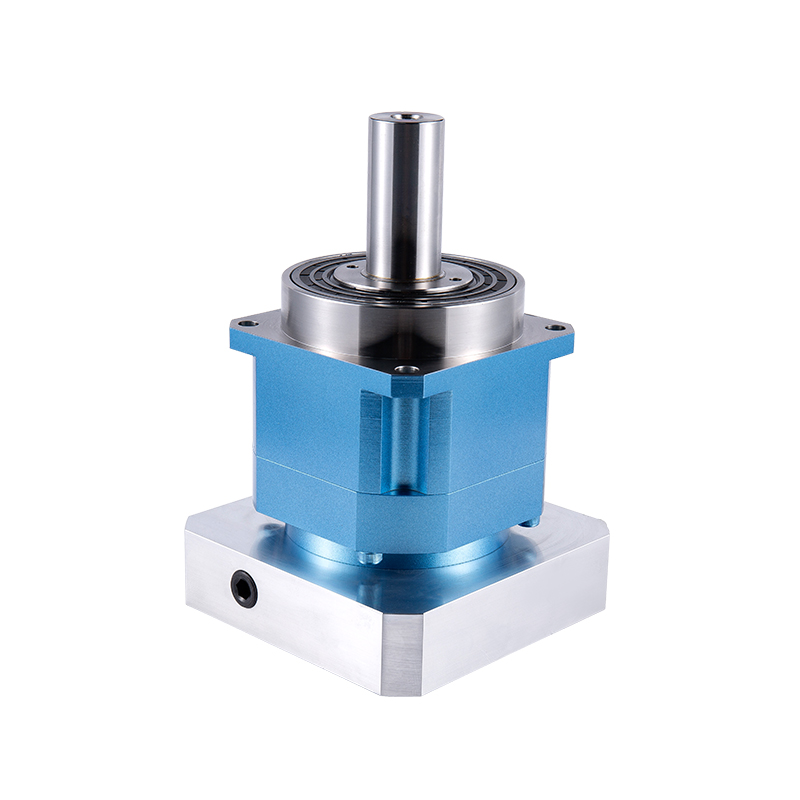

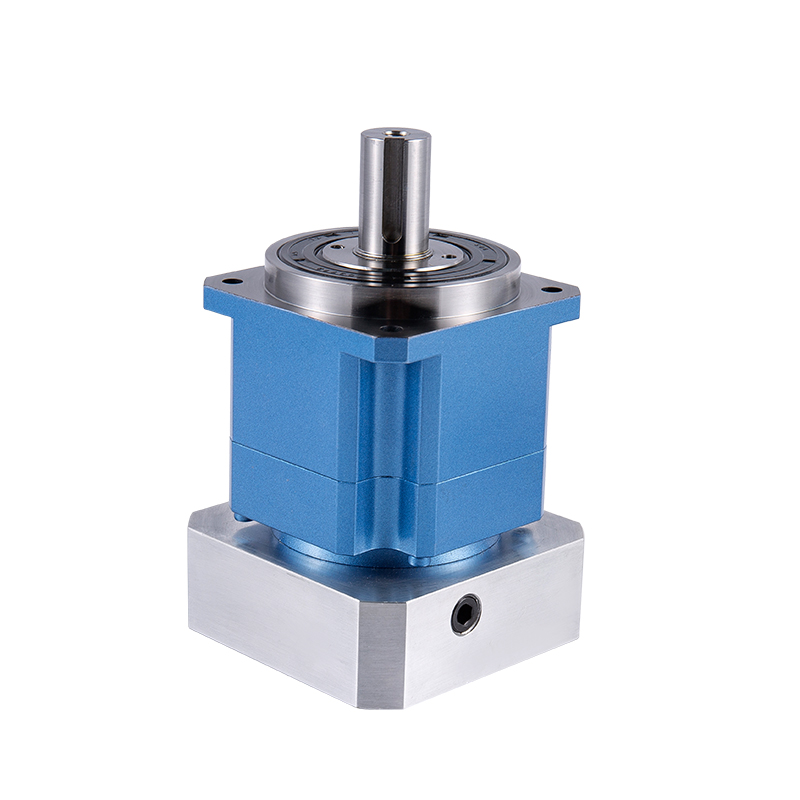

Home / Products / Planetary Reducer / Helical Tooth Transmission Gearbox Planetary Reducer AHL Series for Servo Motor

Helical Tooth Transmission Gearbox Planetary Reducer AHL Series for Servo Motor

About Us

Zhejiang Beitto Transmission Technology Co., Ltd.

The company has always adhered to the Japanese electromechanical cutting-edge R & D technology, adhering to the Japanese meticulous production process, the use of leading design and development technology to research new products, to achieve the optimization and upgrading of the product structure renewal. As a China Helical Tooth Transmission Gearbox Planetary Reducer AHL Series for Servo Motor Manufacturers and Wholesale Helical Tooth Transmission Gearbox Planetary Reducer AHL Series for Servo Motor Factory, we offer Helical Tooth Transmission Gearbox Planetary Reducer AHL Series for Servo Motor.

The city - Pinghu City, Zhejiang Province, National Economic and Technological Development Zone, the province's only one approved by the provincial government of the Japanese investment zone, the National (Jiaxing) Electromechanical Components Industrial Park and the National Torch Plan Pinghu Optical and Mechanical Industrial Base core area, Pinghu City is located in China's most dynamic economy of the Yangtze River delta region, is located in the northeastern part of Zhejiang Province, east of China's economic, financial, and information center -It is located in the northeastern part of Zhejiang Province, neighboring Shanghai to the east and Hangzhou Bay to the south. The city has a land area of 537 square kilometers, a sea area of 1,086 square kilometers and a coastline of 27 kilometers. It has a total population of 800,000 people.

News

-

Introduction to High-Precision Gear Reducer The High-Precision Gear Reducer plays a crucial role in ......

READ MORE -

In the world of precision motion control and power transmission, the planetary gearbox stands as a c......

READ MORE -

Understanding the Role of Right-angled Gearbox Reducer in Modern Machinery How Right-Angled Gearbox ......

READ MORE -

The industrial landscape is constantly pushing the boundaries of automation, requiring smaller, fast......

READ MORE -

Understanding the Fundamental Principles of Harmonic Drive Systems The Unique Mechanical Architectur......

READ MORE -

In the world of precision motion control, the integration of a stepper motor planetary gearbox repre......

READ MORE

EN

EN

English

English русский

русский 日本語

日本語 Español

Español